Product 05

The advantages of blister packaging in the packaging market allow it to thrive even in the downturn of the plastic industry. Nowadays, composite blister packaging not only possesses all the good properties of composite substrates but also enhances quality assurance. Moreover, the structure of blister packaging is diversifying, providing us with various forms of convenience, such as zipper bags, rotating bags, etc.

Classification:

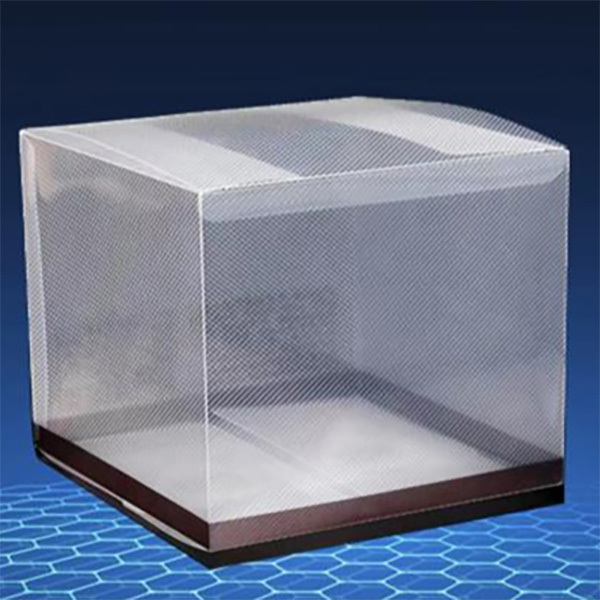

Folding Box Vacuum Forming Series

Keywords: project investment, blister tray

Message

Detailed Description

The advantages of blister packaging in the packaging market allow it to thrive even in the downturn of the plastic industry. Today, composite blister packaging not only possesses all the good properties of composite substrates but also enhances quality assurance. Moreover, the structure of blister packaging is diversifying, providing us with various forms of convenience, such as zipper bags, rotating bags, etc.

Prev

Next

Prev

Next

It is a commonly used packaging method. After heating and softening the plastic sheet, it is adhered to the surface of the mold using vacuum suction to form the desired box.

View DetailsVacuum forming is a type of plastic thermoforming and is a widely used plastic processing technology. Vacuum-formed products are everywhere and play an important role in our daily lives. They are used in packaging, advertising, and decoration. Common materials used in vacuum forming include polyethylene, polypropylene, polyvinyl chloride, ABS, and polycarbonate.

View DetailsThe double-fold blister box is a double-sided folding box packaging product, with two in the middle and three in the middle. This type of folding packaging can better protect items and also well reflect the characteristics of the items. This packaging has a vertical type and can also be hung on shelves. The blister packaging box is roughly the same as the folding box. The blister packaging box can also enhance the price and image of the product itself. At the same time, it can shape and spread the role, having a significant impact on the brand and awareness of the enterprise.

View DetailsVacuum packaging refers to the production of plastic products using vacuum forming technology, and the general term for packaging products with corresponding equipment. The sheet material of vacuum packaging boxes is heated at high temperatures and then vacuum-formed and cooled to create plastic boxes. Vacuum boxes are widely used, including in toy products, stationery, cosmetics, and digital products. For example, customers of cosmetics and digital products mainly use vacuum boxes as inner packaging, with an additional layer of cardboard packaging on the outside. The packaging that uses this type of packaging mainly focuses on beautifying items and vacuum boxes.

View DetailsWhat kind of help do I want to give you?

Please confirm and fill in your information so that we can better serve you!

Note that the content with * is required, thank you!