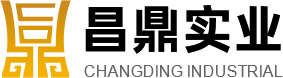

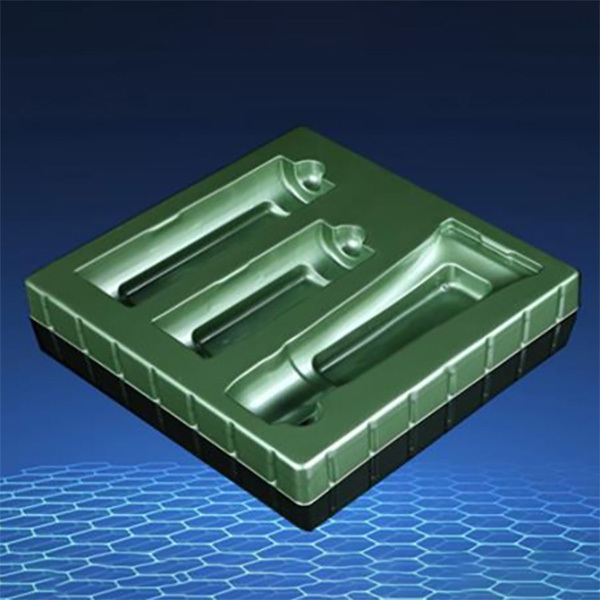

Vacuum packaging is primarily used for separating, shockproofing, and lining products, which often include electronics, IT, industrial parts, toys, stationery, food, crafts, cosmetics, etc. It can package many small products, making the overall appearance of the products more attractive.

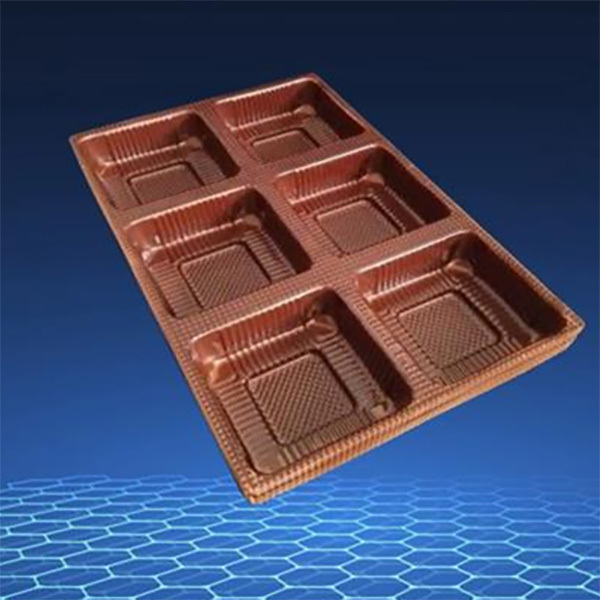

View DetailsBlister packaging is one of the most commonly used packaging materials, providing excellent protection and display for products, and is widely used in various industries. The production process of blister packaging mainly includes mold manufacturing, material pre-processing, blister forming, deburring, and packaging. Mold manufacturing: In the production process of blister packaging, the first step is to create molds that match the shape and Size of the product.

View DetailsBlister packaging is a type of blister product with a cover and a base. When the base and the cover are connected, it is called a semi-blister box. When the base and the cover are separate, it is called a blister box.

View DetailsVacuum packaging has a wide range of applications, including electronic products, medical devices, food, cosmetics, stationery, and other fields. For example, electronic products often use ampoule packaging to protect delicate components such as displays and buttons; medical devices typically use ampoule packaging to protect the surface of medical instruments from damage; food usually adopts vacuum packaging to prevent contamination during transportation and storage; cosmetics generally use vacuum packaging to protect them from environmental damage; stationery is usually packaged in vacuum packaging to protect it from harm.

View DetailsThe application range of vacuum forming packaging is wide, with low prices for equipment and molds, and easy operation of the equipment. Generally speaking, foil vacuum forming can be used for various products in packaging. In daily life, the bubble wraps we see, such as toothbrush cases, cosmetic cases, and hardware cases, are all sheet vacuum packaging, while thick sheet vacuum forming is relatively less used in packaging. Examples include refrigerator liners, television casings, special vehicle casings, luggage, various trays, and pallets.

View DetailsBlister packaging has many advantages such as being lightweight, waterproof, moisture-proof, and dust-proof, effectively protecting products from external environmental influences. In addition, blister packaging also has excellent compressive strength, which can effectively prevent products from being damaged during transportation and storage. Blister packaging is a common form of packaging with many advantages and wide applications. It can effectively protect products from external environmental impacts while enhancing the aesthetics and value of the products.

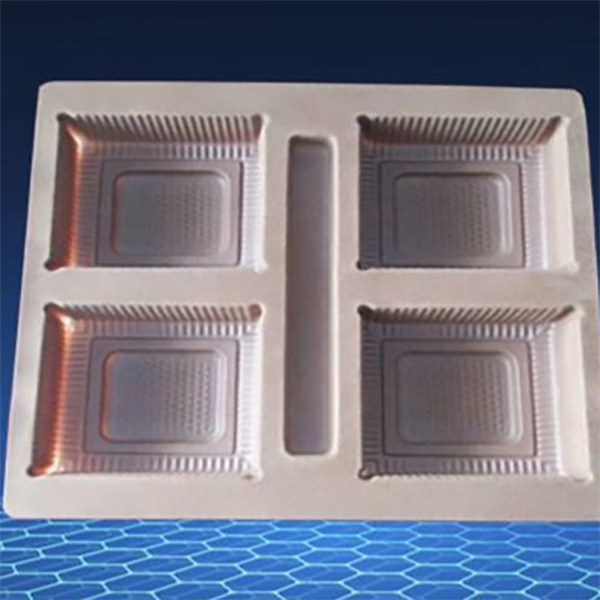

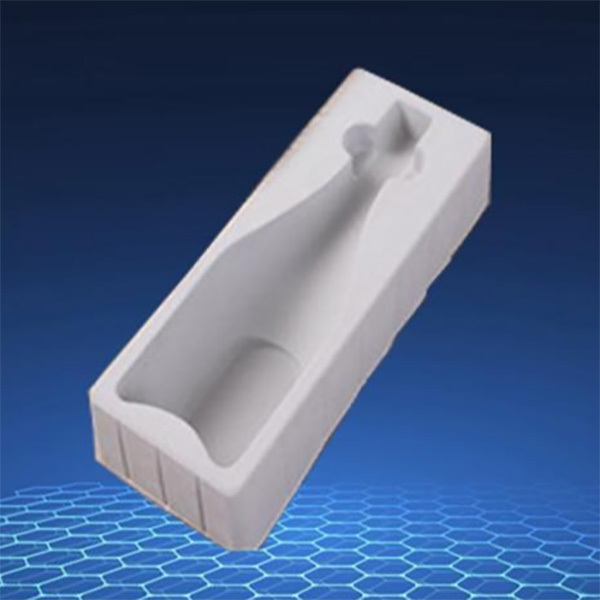

View DetailsA type of plastic processing technology, the main principle is to heat and soften flat plastic sheets, vacuum adsorb them onto the surface of a mold, and cool them to form. It is widely used in industries such as plastic packaging, lighting, advertising, and decoration.

View DetailsBlister packaging has many advantages such as being lightweight, waterproof, moisture-proof, and dust-proof, effectively protecting products from external environmental influences. In addition, blister packaging also has excellent compressive strength, which can effectively prevent products from being damaged during transportation and storage. Blister packaging is a common form of packaging with many advantages and wide applications. It can effectively protect products from external environmental impacts while enhancing the aesthetics and value of the products.

View DetailsDesigning molds: Design corresponding molds according to the size and shape of the vacuum-formed box.

View DetailsThe advantages of blister packaging in the packaging market allow it to thrive even in the downturn of the plastic industry. Nowadays, composite blister packaging not only possesses all the good properties of composite substrates but also enhances quality assurance. Moreover, the structure of blister packaging is diversifying, providing us with various forms of convenience, such as zipper bags, rotating bags, etc.

View Details