It is a commonly used packaging method. After heating and softening the plastic sheet, it is adhered to the surface of the mold using vacuum suction to form the desired box.

View DetailsVacuum forming is a type of plastic thermoforming and is a widely used plastic processing technology. Vacuum-formed products are everywhere and play an important role in our daily lives. They are used in packaging, advertising, and decoration. Common materials used in vacuum forming include polyethylene, polypropylene, polyvinyl chloride, ABS, and polycarbonate.

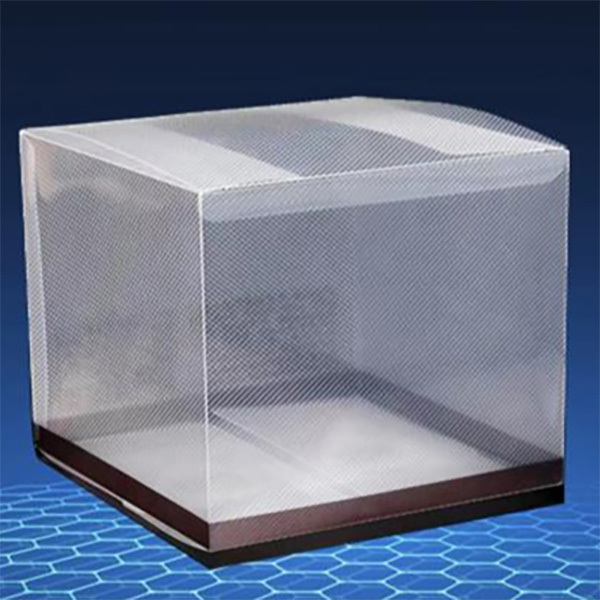

View DetailsThe double-fold blister box is a double-sided folding box packaging product, with two in the middle and three in the middle. This type of folding packaging can better protect items and also well reflect the characteristics of the items. This packaging has a vertical type and can also be hung on shelves. The blister packaging box is roughly the same as the folding box. The blister packaging box can also enhance the price and image of the product itself. At the same time, it can shape and spread the role, having a significant impact on the brand and awareness of the enterprise.

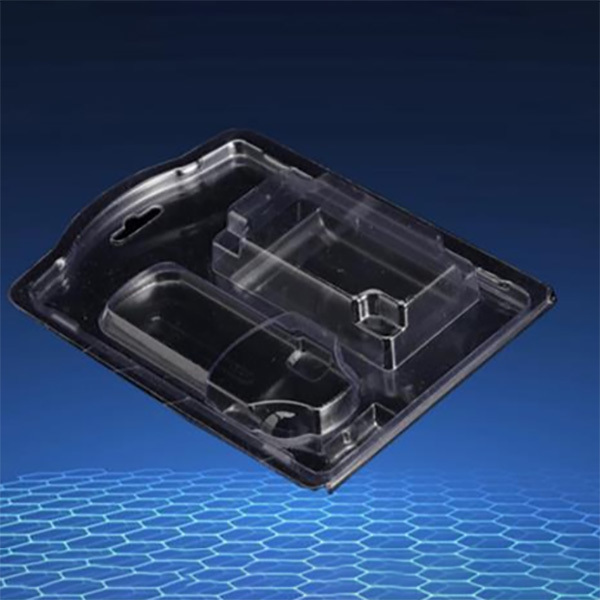

View DetailsVacuum packaging refers to the production of plastic products using vacuum forming technology, and the general term for packaging products with corresponding equipment. The sheet material of vacuum packaging boxes is heated at high temperatures and then vacuum-formed and cooled to create plastic boxes. Vacuum boxes are widely used, including in toy products, stationery, cosmetics, and digital products. For example, customers of cosmetics and digital products mainly use vacuum boxes as inner packaging, with an additional layer of cardboard packaging on the outside. The packaging that uses this type of packaging mainly focuses on beautifying items and vacuum boxes.

View DetailsThe application range of vacuum forming packaging is wide, with low prices for equipment and molds, and easy operation of the equipment. Generally speaking, foil vacuum forming can be used for various products in packaging. In daily life, the bubble wraps we see, such as toothbrush cases, cosmetic cases, and hardware cases, are all sheet vacuum packaging, while thick sheet vacuum forming is relatively less used in packaging. Examples include refrigerator liners, television casings, special vehicle casings, luggage, various trays, and pallets.

View DetailsVacuum forming is the process of fixing thermoplastic sheets or sheets onto a mold, heating the material to its softening temperature with a heater, and quickly removing the air between the sheet and the mold using a vacuum pump, allowing the material to adhere to the surface of the mold and be demolded after cooling. This method of forming relies on vacuum force to stretch and deform the sheet.

View DetailsThe double-fold blister box is a double-sided folding box packaging product, with two in the middle and three in the middle. This type of folding packaging can better protect items and also well reflect the characteristics of the items. This packaging has a vertical type and can also be hung on shelves. The blister packaging box is roughly the same as the folding box. The blister packaging box can also enhance the price and image of the product itself. At the same time, it can shape and spread the role, having a significant impact on the brand and awareness of the enterprise.

View DetailsHigh transparency: The vacuum-formed box is made of colorless transparent PVC or PET plastic, which has good transparency and can display the appearance and color of the product.

View DetailsVacuum forming products mainly produce high-quality and various specifications of electronic vacuum packaging, stationery vacuum packaging, toy vacuum packaging, high-quality vacuum packaging, PVC, PET, PP, PS, GAG, flocking and other high-quality plastic materials, hardware vacuum packaging, food vacuum packaging, daily chemical gift craft vacuum packaging. Vacuum packaging is of high quality and low price, can beautify your products, and attract more customers.

View DetailsBlister packaging is one of the most commonly used packaging materials, providing excellent protection and display for products, and is widely used in various industries. The production process of blister packaging mainly includes mold manufacturing, material pre-processing, blister forming, deburring, and packaging. Mold manufacturing: In the production process of blister packaging, the first step is to create molds that match the shape and Size of the product.

View Details