A type of plastic processing technology, the main principle is to heat and soften flat plastic sheets, vacuum adsorb them onto the surface of a mold, and cool them to form. It is widely used in industries such as plastic packaging, lighting, advertising, and decoration.

View DetailsIn terms of the variety and quantity of resource consumption, vacuum soft packaging has incomparable advantages over other forms of packaging. Vacuum packaging materials are relatively lightweight, soft, and also easy to fold and package. The recycling and transportation of waste materials from vacuum soft packaging can be said to be quite convenient. There are many waste disposal methods, which can vary according to the nature of the waste. Methods such as landfilling, incineration, decomposition, and recycling can be adopted.

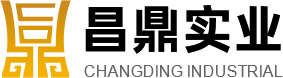

View DetailsVelvet flocking vacuum forming

Velvet ampoules are a type of ampoule tray made from special materials. The surface of ordinary plastic hard sheets is coated with a layer of velvet material, giving the tray a velvet feel, which is used to enhance packaging quality.

View DetailsFlocked ampoule packaging is a product that is less commonly used and produced among ampoule products. In the item packaging industry, there are not many items packaged with flocked ampoule packaging. Generally, it serves as bottom support. Flocked ampoule packaging is considered a relatively high-end item packaging in terms of appearance, looking beautiful and elegant. It is usually used for packaging high-end items such as chocolates, health products, cosmetics, gifts, jewelry, glasses cases, watch boxes, and alcoholic products. The main material for these vacuum-formed products is PS material. Flocking involves gluing a thin layer of fine fibers onto the surface of the material. This has resulted in the formation of flocked vacuum-formed products. Flocked vacuum-formed products are aesthetically pleasing, soft to the touch, and come in various colors. You can choose the appropriate color based on the article's images. At the same time, the product becomes more attractive, making it easier for consumers to develop a favorable impression. The desire to purchase items must have the unique advantages of item packaging. Flocked plastic packaging products are very valuable packaging products in use.

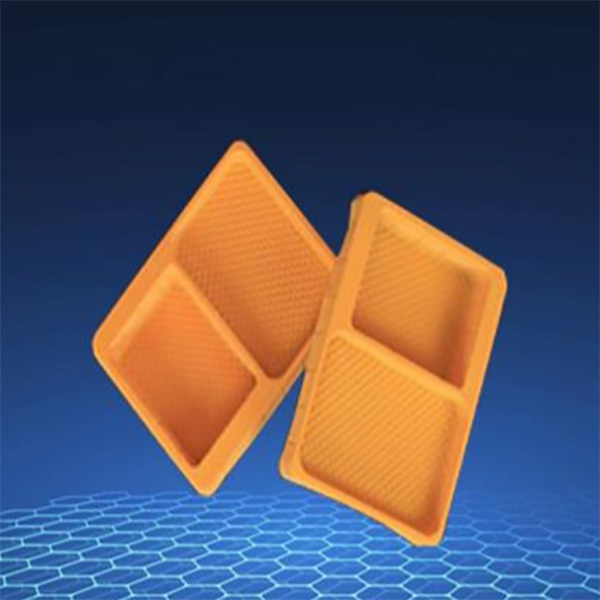

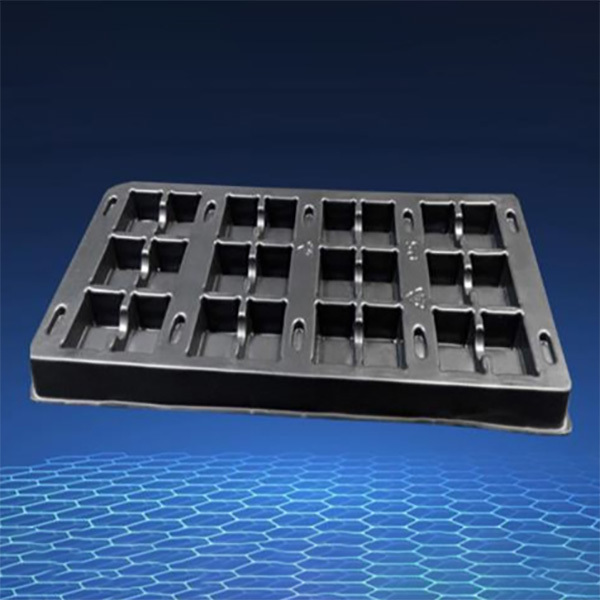

View DetailsVacuum-formed trays made of special materials. The vacuum heat pressing process forms a three-dimensional structure, which has good mechanical strength and elasticity.

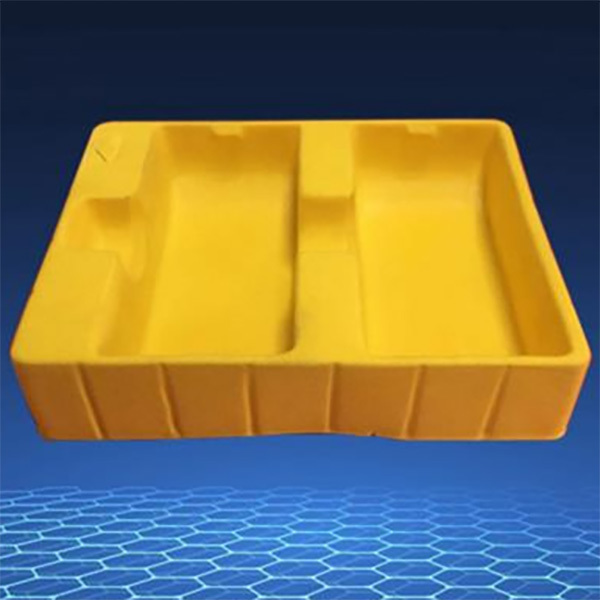

View DetailsThe anti-static blister tray is made of special material blistering and PP plastic. The surface resistance value of the material is less than 10 to the power of 6 or between 10 to the power of 6 and 10 to the power of 11.

View DetailsThe anti-static blister tray is made of special material blistering and PP plastic. The surface resistance value of the material is less than 10 to the power of 6 or between 10 to the power of 6 and 10 to the power of 11.

View DetailsThe anti-static blister tray is made of special material blistering and PP plastic. The surface resistance value of the material is less than 10 to the power of 6 or between 10 to the power of 6 and 10 to the power of 11.

View DetailsThe anti-static blister tray is made of special material blistering and PP plastic. The surface resistance value of the material is less than 10 to the power of 6 or between 10 to the power of 6 and 10 to the power of 11.

View DetailsThe anti-static blister tray is made of special material blistering and PP plastic. The surface resistance value of the material is less than 10 to the power of 6 or between 10 to the power of 6 and 10 to the power of 11.

View Details